Resources

A collection of free resources to help you raise funds and share the work we do

By Michael Grey

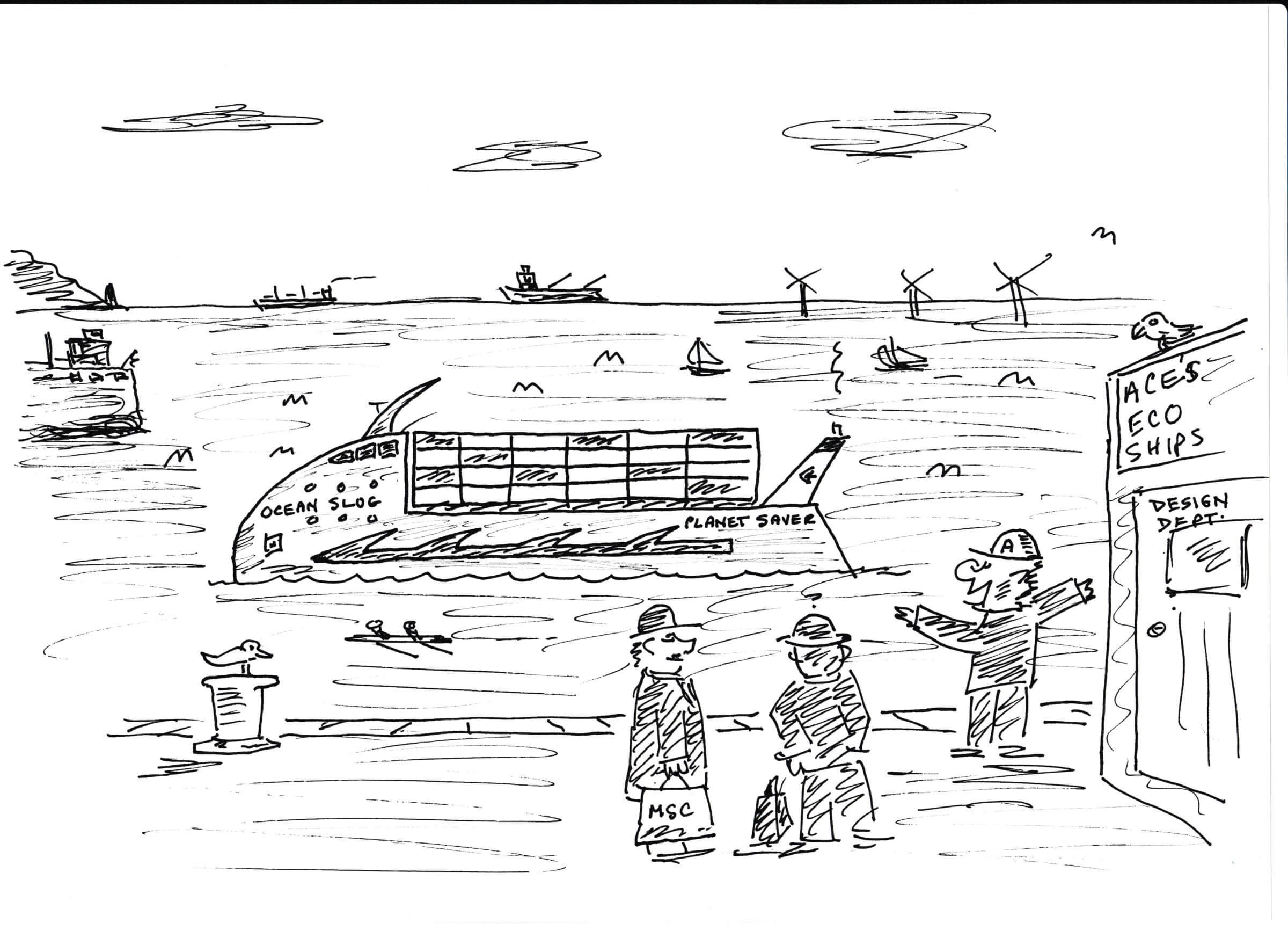

It is curious how the expertise of experts changes over time, which ought to emphasise the fact there is no such thing as ‘settled science’. For years people who designed ships clung to the notion that there was no point in making ships aerodynamic because of a theory that streamlining failed to offer any positive advantages until you got up to about 90mph. It is why ordinary saloon cars were shaped like bricks and trains had flat fronts. Aeroplanes were different.

Any seafarer could have pointed out the error in this idea, knowing perfectly well that a ship immediately slowed down when the wind blew from forward of the beam. A conventionally designed general cargo ship with an advertised 14 knot service speed would lose a couple of knots with a 20knot wind from ahead, blowing against that great flat bridge front. It was something that would enrage charterers, but there was no arguing with the scrupulously kept metrological logbook.

Their arguments against any form of streamlining were also reinforced by the shipbuilders, who delighted in building flat slabs of steel and would suggest that two-, or even three-dimensional curves in a steel plate would be prohibitively expensive. Between them these professionals managed to keep the seafarers silent and ships built of squares rather than curves.

The soaring price of fuel was the first incentive to look once again at this problem and it was the Japanese shipbuilders who began to look more creatively at the way that air moves around a high superstructure. They found that it was helpful to use vertical spoilers (like those on the back of racing cars) to smooth the airflow around the accommodation block on big tankers and bulk carriers. Small but useful improvements in fuel consumption were noted.

And over the years there have been other attempts to make a big ship rather less of an obstacle to the wind coming from forward of the beam, by shaping the superstructure, slimming down the block, or redesigning it completely, helped of course by the fact that crews are smaller these days and you do not need so much accommodation on any cargo ship as was once required.

Design rethink

In recent years, with both high fuel prices and the added incentive of environmental pressures, the science of hydrodynamics to optimise the hull beneath the waterline has been paralleled by similar improvements on the aerodynamic front. There are certain classes of ship, such as the huge high-sided vehicle carriers and fleets of big containerships that, with their vast shapes above the waterline, are pushing a great deal of air ahead of them.

Curving the shape of the superstructure of car carriers really does make a useful difference to fuel consumption. Similarly, the newer enthusiasm for building a high, elegantly shaped ‘windshield’ ahead of the great slab of containers on the foredeck is similarly helpful. It might only be in single figure percentages, but on long oceanic voyages it all adds up, while it can also contribute to the environmental improvements that all ships must now be able to demonstrate.

Dramatically changing the shape of a ship can have its downside. A curved bridge front can confuse the lookout. A ship I served on, where the designers had persuaded the owners to employ streamlining, looked good and far faster than she was, but the sloping bridge front meant that dew, rain, ice and snow sat on the windows and dimmed our vision. This meant the officer of the watch had to go and get wet and cold on the bridge wings. It is why, in case you haven’t noticed, modern windows slope inwards from the top.

Perhaps you learn from your mistakes and ship designing is no different to any other science, but today most are agreed that aerodynamics can help you along.